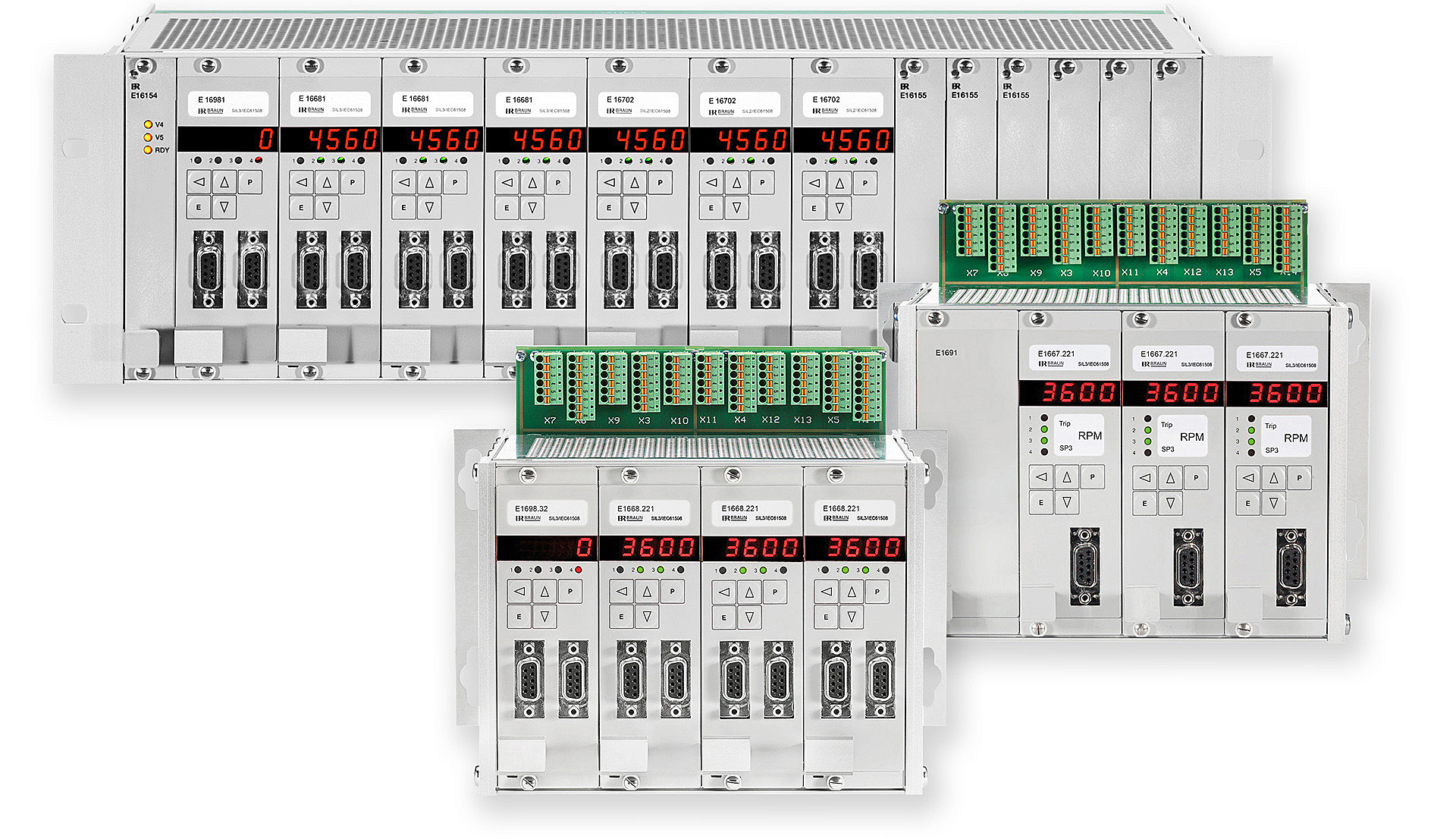

“State of the art” Overspeed Protection Systems with triple channel redundancy (TMR)

Our production focuses on monitoring and protection systems to protect all types of “Rotating Equipment” and “Turbomachinery”. Our protection systems include the protection of turbines, compressors, and expanders against overspeed trip and other criteria such as emergency stop, overpressure, and overheating. We claim to be the world’s technological market leader in this field.

BRAUN Protection Systems monitor this equipment with their unique TMR architecture and guarantee the trouble-free operation of safety-critical “Rotating Equipment”. And this, if necessary, at the SIL3 safety level to prevent harm to man and machine.

Single Channel devices utilizing 1oo1 or 1oo2 do not ensure continued operation of the monitored machinery. In such cases, fault detection results in an operational shutdown.

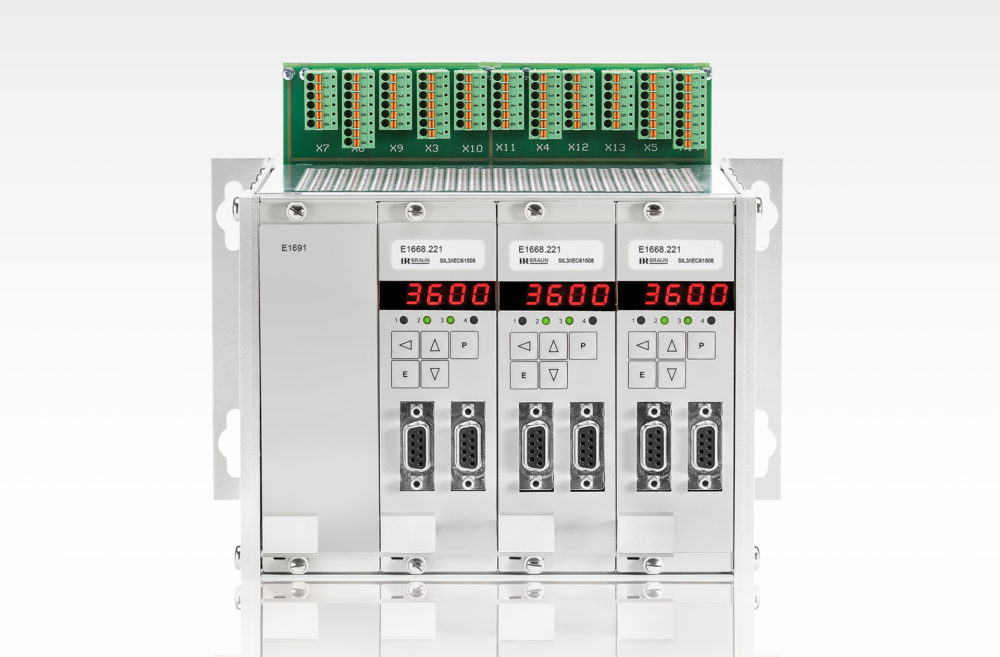

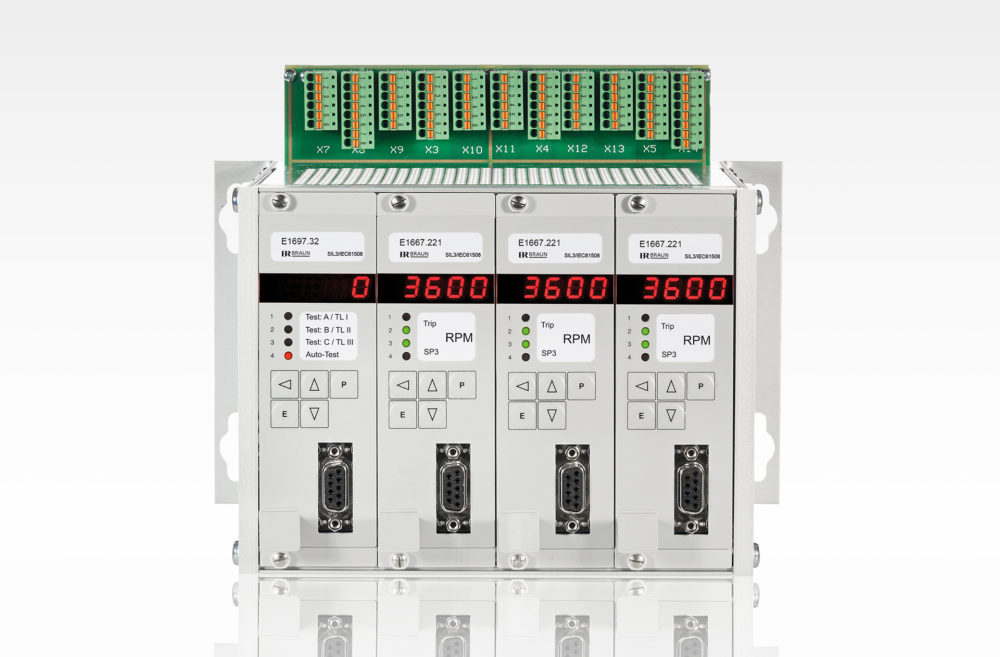

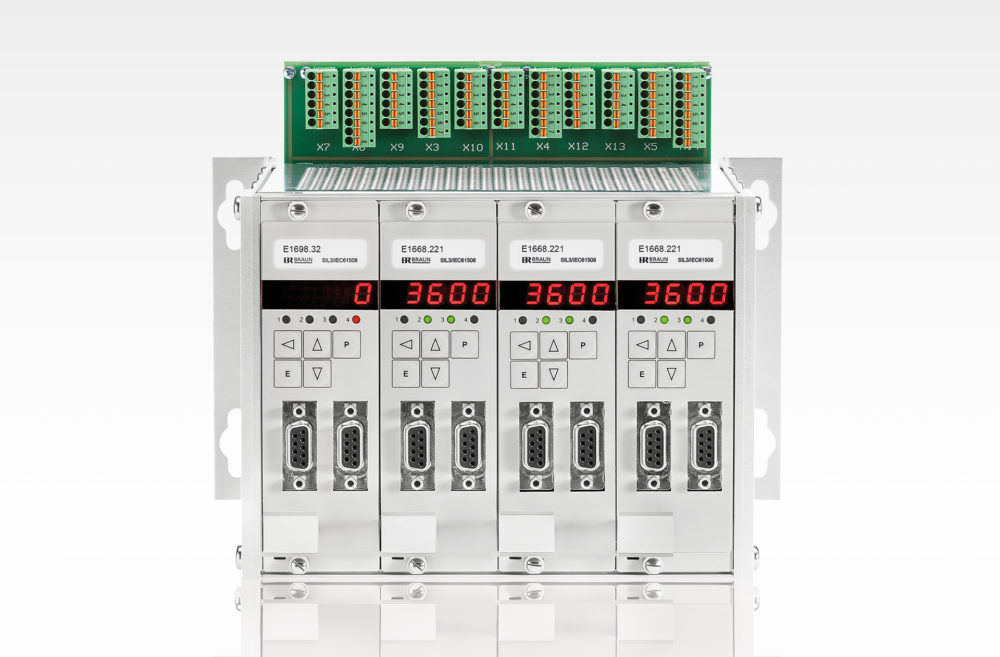

However, with Triple Channel redundancy incorporating 2oo3 evaluation, this is not the case. When system shutdown is not an option, our worldwide unique and true 2oo3 architecture provides the most comprehensive protection against spurious alarm signals and thus ensures continuous operation of the machine. This concept incorporates the monitoring of each trip criterion within each of the three Monitors in 2oo3 evaluation, not only for the complete system. In addition, integrated and sophisticated self-tests are carried out fully automatically during operation, thus guaranteeing the constant availability of the protection system.

Our competitors’ products may release an unjustified shutdown of your machines – our systems keep your production facilities up and running.

E16 System product matrix (overview), standard solutions in 2oo3 architecture

| Model | SIL3 | PFD Value | Test Interface |

Test Generator |

Automatic Test of 2oo3 Solenoid by E16 |

PROFIBUS Interface |

| E16x342 | ● | 7,71 · 10-5 | ● | 1 | ||

| E16x352 | ● | 7,71 · 10-5 | ● | 2 | ||

| E16x346 | ● | 8,41 · 10-6 | ● | ● | 1 | |

| E16x356 | ● | 8,41 · 10-6 | ● | ● | 2 |