Differential-Hall-Effect Speed Sensors Series A5S – the various types and their characteristics

The correct choice of sensor is always a prerequisite to achieving a successful solution. Our A5S speed sensors are based on the proven Differential-Hall-Effect principle. Their low end of 0 Hz allows monitoring the machine down to zero speed. In addition, they are contact-free, wear-free, and maintenance-free. Furthermore, they are unsusceptible versus external magnetic stray fields and machine vibration. These characteristics make the series of A5S sensors especially suited to all applications where high accuracy and reliability are at a premium. In contrast, other sensors like magnet-inductive or static Hall-sensors do not meet these demands.

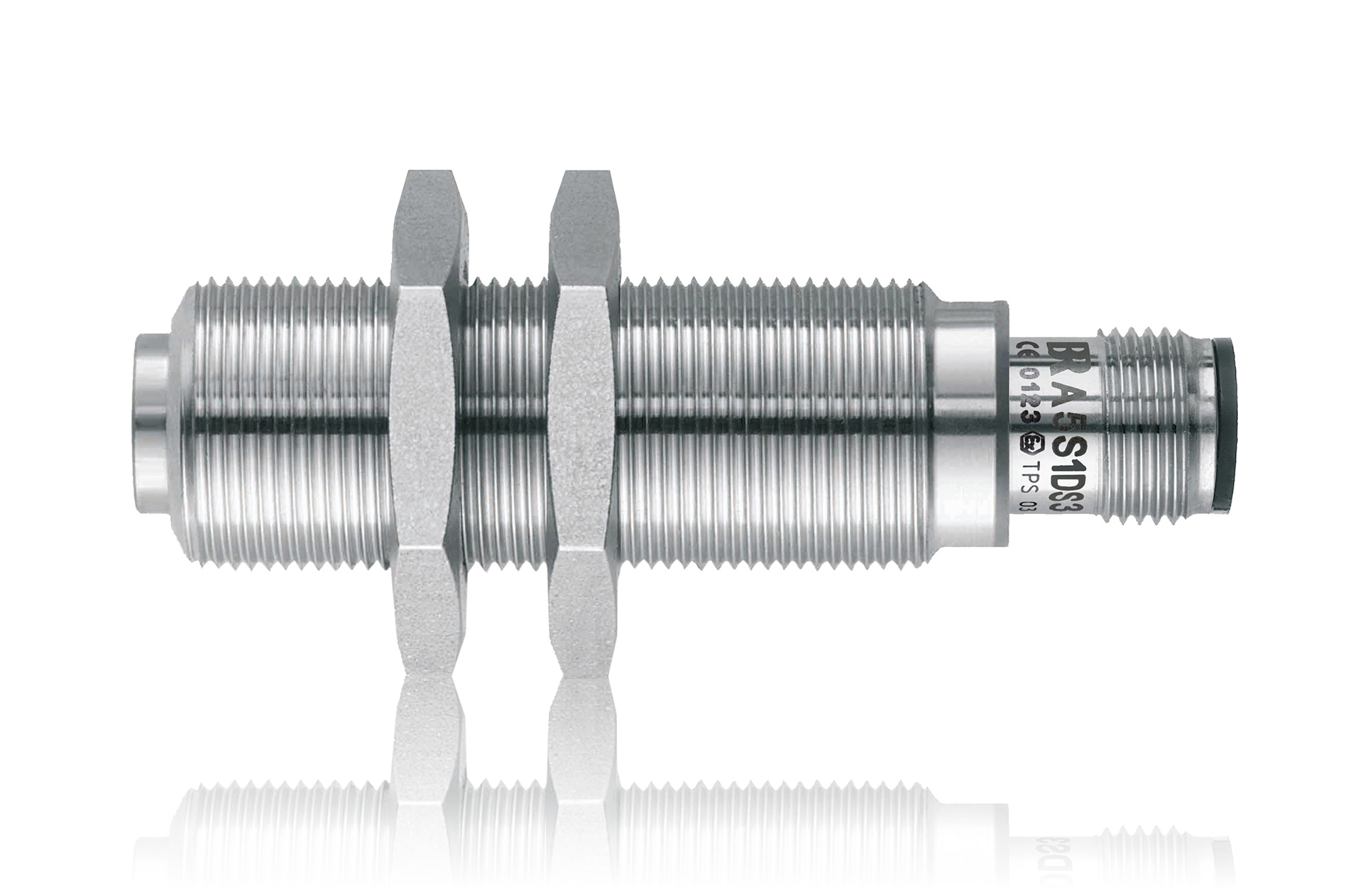

Each sensor in the series is available in various lengths and diameters and has a choice of connections. However, functionally, all sensors have the same characteristics.

The stainless steel sensor housing is sealed at the front and is pressure-resistant (> 200 bars). A flat shaft is available or with a screw-in thread M12x1, M14x1, M14x1,5, M16x1, M16x1,5, M18x1, M18x1,5, M22x1, 5/8-18UNF-2A. Customized dimensions and thread specifications are possible.

To meet the specific requirements of hazardous areas, we provide specialized types certified for ATEX, UKEX, IECEx, and KCs and approved for other international standards such as UL/CSA.

- For Hazardous Areas (Zone 0-1), an intrinsically safe implementation in conjunction with our Isolating Barrier D461

- For Hazardous Areas (Zone 2), a non-sparking (non-incendive) variation is available