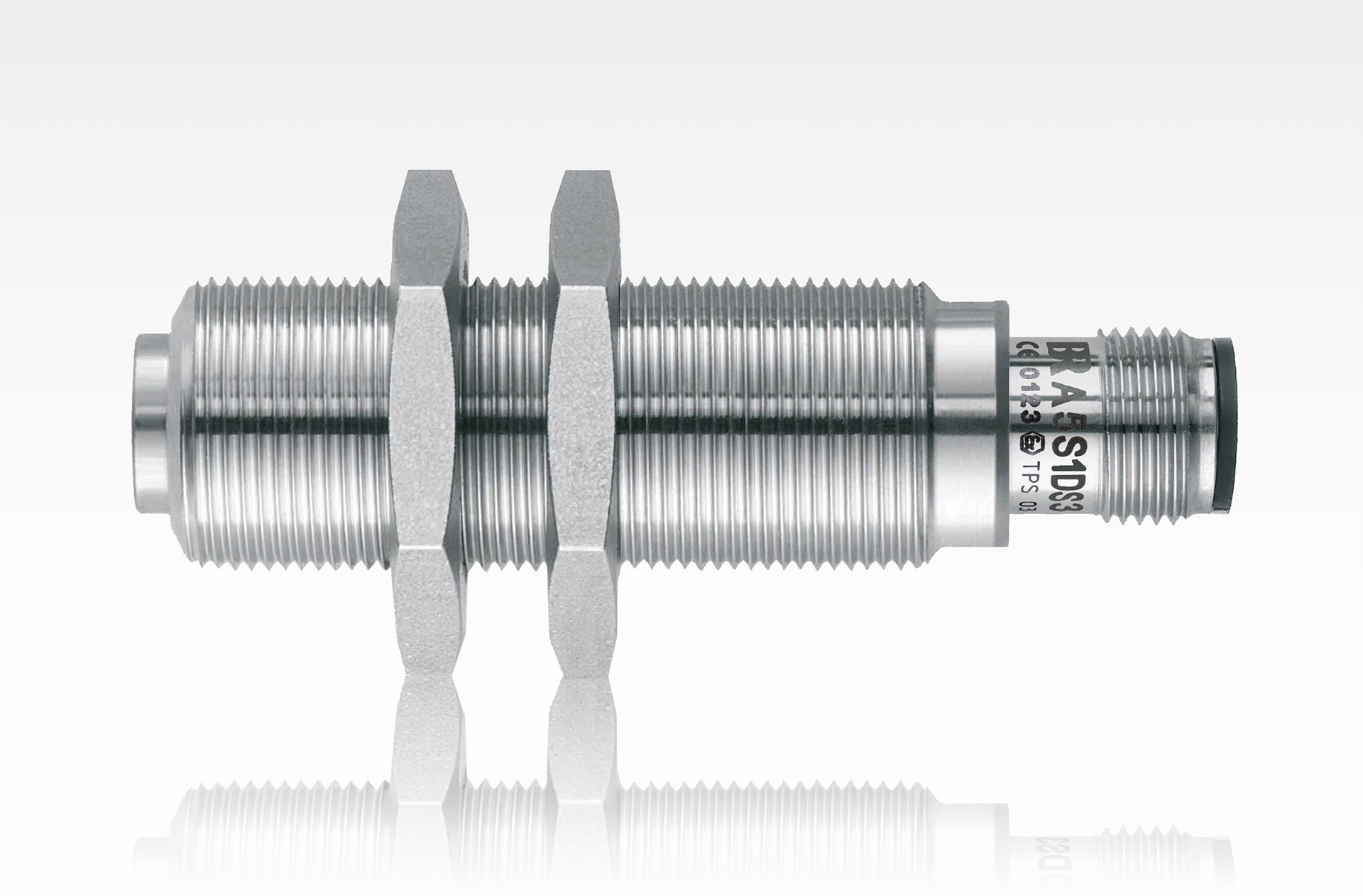

A5S1DD3

Sensor A5S1DD3 for detection of rotational speed and direction of rotation in Hazardous Areas Zone 0 or 1 and highest safety requirements up to SIL3

The BRAUN Speed Sensors Series A5S1 are TÜV certified for SIL3 acc. IEC 61508:2010 and therefore meet the high SIL3 standards. To meet the specific requirements of hazardous areas (Ex Zone 0 or 1), we provide these specialized types which are certified for ATEX, UKEX, IECEx, as well as for other international standards such as UL/CSA. A5S1 sensors, in conjunction with our Isolating Barrier D461, provide an intrinsically safe implementation to meet these specific requirements.

The correct choice of sensor is always a prerequisite to achieving a successful solution. Therefore BRAUN A5S1 sensors base on the proven Differential-Hall-Effect principle. Their low end of 0 Hz allows monitoring the machine down to zero speed. They are contact-free, wear-free, maintenance-free, and unsusceptible versus external magnetic stray fields and machine vibration. These characteristics make the series of A5S1 sensors especially suited for all applications where high accuracy and reliability are at a premium.

In contrast, other sensors like magnet-inductive or static Hall-sensors do not meet these demands.

Each sensor in the series is available in various lengths and diameters and comes with a choice of connections. However, functionally all sensors have the same characteristics.

The stainless steel sensor housing is sealed at the front and is pressure-resistant (>200bar). A flat shaft is available or with a screw-in thread M12x1, M14x1, M14x1,5, M16x1, M16x1,5, M18x1, M18x1,5, M22x1, 5/8-18UNF-2A. Customized dimensions and thread specifications are possible.

Key Features

- SIL3/IEC 61508:2010 certified by TÜV

- Detection of rotational speed and direction of rotation in Hazardous Areas Zone 0 or 1

- Speed range from 0 Hz to 25 kHz

- Dual Channel,

1 track = rotational speed as frequency, 1 track = F/R status as binary signal - Air gap to the target/pole wheel up to 2.5 mm (depending on the profile size)

- Temperature range -40…+125 °C (-40…+255 °F)

- Differential principle diminishes the influence of external magnetic stray fields and machine vibration

- Sealed stainless steel enclosure > 200 bar pressure to the sensor tip

- Available for connection via tight plug, or with fixed Teflon® cable

- Powerful square wave output signal equally high over the entire speed range

- Sensor short circuit proof and protected versus polarity error

- Accepting fine and coarse profiles, as gear wheels, slots, cams, holes in any ferrous material

- Requires Isolating Barrier D461

- For installation in hazardous areas as intrinsically safe operating resource

- ATEX, UKEX, IECEx certified for Ex ia IIC T4/T6 Ga

- QPS / QPSus certified for Class I, Div 1, Groups A, B, C, D according to UL and CSA standards

Benefits

- Contact-free with a large air gap, so the potential for damage is eliminated

- Wear-free due to its unique design principle

- Maintenance-free during Lifetime, therefore minimized TCO

- Unsusceptible versus external magnetic stray fields and machine vibration

- Operates down to zero speed

- Cannot be damaged by faulty wiring

- Almost every target profile can be used

- A5S1 sensors do not influence each other; no mounting distance in between is required